What are the three major trends presented by the LED industry

1. Industry Overview

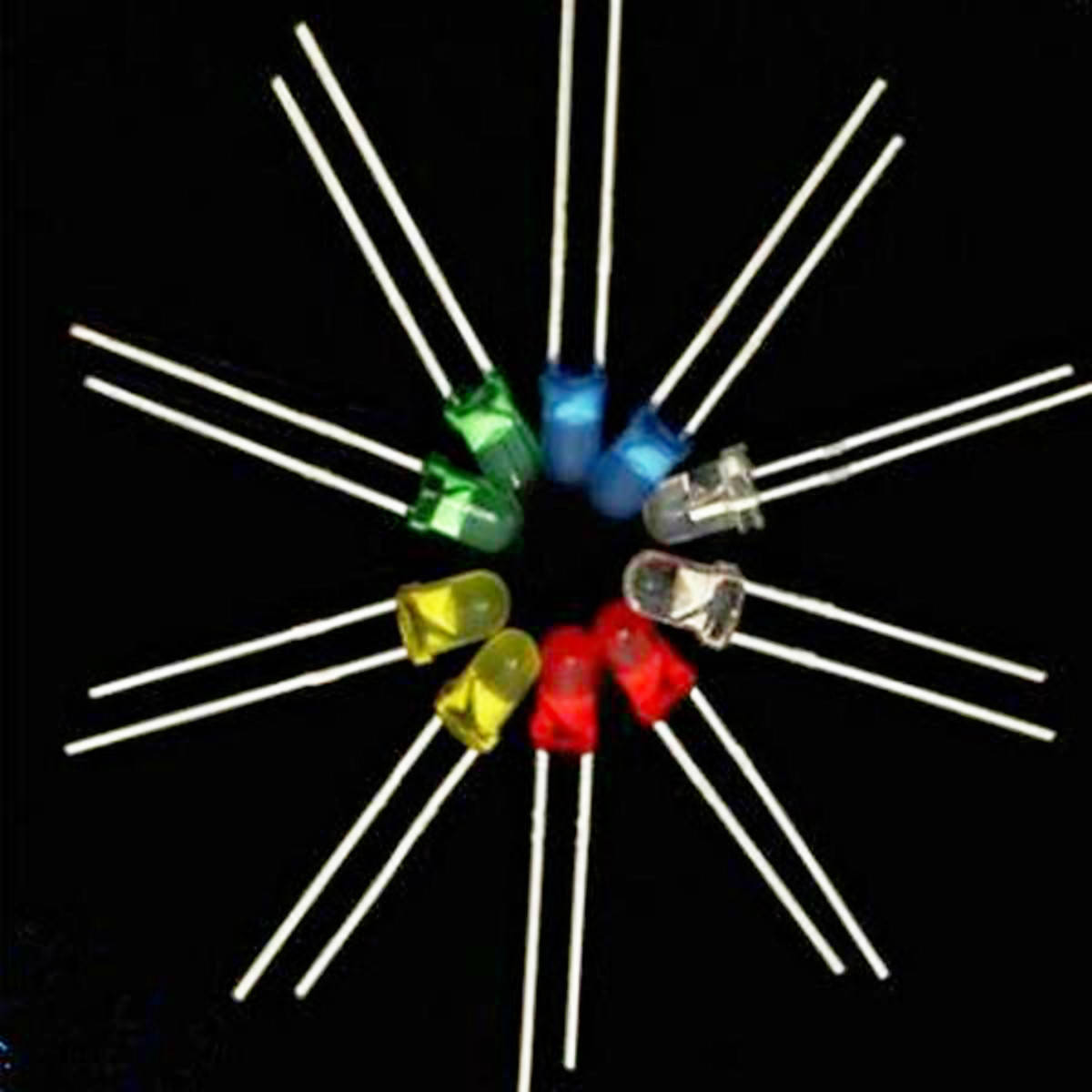

LED (Light Emitting Diode) is a semiconductor light-emitting device that can convert electrical energy into light energy. It is made of compounds containing gallium (Ga), arsenic (As), phosphorus (P), nitrogen (N) and other elements, which can emit visible light when electrons and holes recombine. When the above elements are combined in different ways, different colors of light can be produced, such as gallium arsenide emitting red light, gallium phosphide emitting green light, silicon carbide emitting yellow light, etc., which can then form visible light with diverse colors.

Related report: Beijing Puhua Youce Information Consulting Co., Ltd.'s "2018-2025 LED Industry Supply and Demand Pattern Trends and Investment Strategy Consulting Report"

In addition to its versatile colors, LED has unparalleled advantages in energy saving, environmental protection, long lifespan, and resistance to damage compared to other lighting methods, making it widely used in real life. According to statistics, as of the end of 2016, the size of the LED application market had grown by 19.36%. Among them, lighting remains the main driving force for the development of the application market, with a growth rate of about 32.5% in 2015, accounting for 45% of the domestic application market. In 2016, the size of the LED application market increased by 23.2%, with the lighting market growing at a rate of about 30.3%, accounting for 47.60% of the domestic application market. It is the first driving force of the application market and continues to maintain a stable growth trend. Among them, automotive lighting, landscape lighting, and backlighting are the main components, accounting for more than 70% of the total. The main reason is that the lighting environment in these three fields is complex and varied, and the light source must withstand various tests such as temperature changes, vibration, dust accumulation, and long usage time. Currently, only the advantages of LED may meet these usage needs. As of the end of 2016, in addition to the top three application fields in lighting, visible light communication, ultraviolet LED, and agricultural lighting (the three new fields) continued to develop strongly, accounting for about 2.6% of the application field share, and outdoor display accounted for 7.1%.

The LED industry in our country started in the early 1970s. Due to the limited application areas at that time, the development of the industry was relatively slow, mainly dominated by scientific research institutes or enterprises with research institute backgrounds. A series of factors such as limited application areas, high unit production costs, and immature technology resulted in very weak industrialization capabilities in the early stages of development.

After more than 40 years of development, especially since entering the 21st century, China's macro economy has continued to grow, and the demand for energy conservation and emission reduction has been increasing. Coupled with national policy support, LED technology has continuously made breakthroughs. China's LED industry has initially formed a relatively complete industrial chain, including LED epitaxial wafer production, LED chip preparation, LED chip packaging, and LED product application. After experiencing the path of buying devices, chips, and epitaxial wafers, China's LED industry has now achieved independent production of epitaxial wafers and chips. Since 2005, China's LED product technology innovation and application development capabilities have gradually improved, and the position of device reliability research has become increasingly prominent. Testing technology and standards have also become hot topics, marking that China's LED industry has entered a new stage of development.

In the entire LED industry, the upstream is LED chip epitaxy, the midstream is LED packaging, and the downstream is LED applications. With the gradual extension of LED downstream application fields, the product application scope is becoming increasingly wide, which has a direct impact on the midstream packaging process. In recent years, China's LED packaging capability has improved rapidly, with a wide range of varieties that can package various sizes and colors of LED devices, including single tube, composite tube, digital display, SMD devices, etc. Compared to the epitaxial and chip industries, China's LED packaging industry is the most competitive, large-scale, and technologically advanced. At present, the domestic packaging industry has become an important LED packaging production base in the world.

With the rapid development of gallium nitride indium material technology, blue, green, and white LED based on blue chips have been industrialized. In terms of application scope, white LED is the most widely used LED product. Its emergence has expanded the application field of LED to general lighting (including indoor and outdoor lighting), backlight (widely used in laptops, mobile phones, LCD TVs, LCD displays, MP3, MP4, iPod, etc.), indoor and outdoor full-color display screens, special lighting (such as medical lamps, projection and photography lamps), and specialized lighting (such as mining lamps, aerospace lamps, military lamps). However, at the current level of technology, no LED chip can directly emit white light, and it needs to be achieved through light color composite technology, so its packaging technology is also the most difficult. The packaging of white LED, especially high-power white LED, requires solving problems in various disciplines including optics, thermodynamics, mechanics, electronics, etc., which is the main standard for measuring the technical level of LED packaging enterprises. The conductivity, heat dissipation, and mechanical characteristics of the LED bracket depend heavily on its quality.

2. Future Development Trends

(1) With the decrease in cost prices, LED lighting will become a key focus of development

Benefiting from the improvement of light efficiency, the cost of LED chips can be controlled under the same lighting intensity. In the downstream links of the industrial chain, LED packaging introduces new technologies such as COB (chip on board packaging) and packaging materials with better heat dissipation performance, further improving the luminous efficiency of packaging devices. The design of LED light sources and lamps tends to be integrated, and the design level is better than traditional light sources, which also contributes to the cost control of the final product.

With the gradual elimination of incandescent bulbs worldwide, LED lighting will usher in a rare development opportunity and become a key focus of the lighting industry.

(2) The integration of various links in the industry is accelerating, and the market concentration is gradually increasing

The upstream of the LED industry has the characteristics of technology intensive and capital intensive, while the middle and downstream have the characteristics of capital intensive, technology intensive, and labor-intensive. Scale advantage is an important means for enterprises in the industry to control costs and improve their competitiveness. Therefore, low-end small enterprises without scale advantage will find it difficult to continue investing in research and development and market expansion, and thus it will be difficult to survive in the industry. In recent years, the domestic LED industry has increased its integration efforts, and small enterprises are gradually withdrawing. The number of internal enterprises in the industry has changed from a continuous increase a few years ago to a basically stable level. Overall, the quantity has not changed much, but the market concentration has significantly increased. Large and medium-sized enterprises account for more than 60% of the expanded packaging enterprises with an output value of over 100 million yuan. From the perspective of the industry lifecycle, the industry is transitioning towards the later stage of growth and will gradually enter a mature stage in a few years, forming a situation where multiple large enterprises lead the market standards, improve product quality, and remain stable.

(3) Continuous investment in research and development will promote a more complete industrial chain and increase the added value of product technology

At present, China's LED industry as a whole is at the lower end of the value chain, especially in the chip epitaxial link where the added value of products is relatively low compared to the international advanced level. However, the strength of large domestic LED enterprises is gradually improving, and research and development investment is increasing. In addition, China's packaging industry is at an international advanced level. The high standards of the packaging industry will in turn promote the accelerated development of the chip epitaxial industry, which will drive the development of the entire industry and float upstream in the value chain.